AI In Supply Chain Management: 9 Ways Artificial Intelligence Transforms Logistics

Learn how AI Logistics and AI in supply chain provide real-time visibility, automate paperwork, and reduce costs across logistics operations.

Table of Contents

AI in supply chain uses advanced data analysis and algorithmic models to forecast demand, optimize inventory, plan efficient routes, deliver real-time visibility across the network, and detect supplier risks.

The global market for AI in logistics and supply chain totaled $9.15 billion in 2024 and may expand to $40.53 billion by 2030 (28% CAGR), according to AI-SCM analytics. Not to mention that 78% of global companies now employ AI in at least one function.

Our AI Adoption 2025 report at JetRuby shows corporate AI budgets surged 92% over the past two years. The market keeps expanding fast, and decision-makers now treat AI as a core tool, not a side project.

Below, we outline 9 key benefits and two case studies that confirm the benefits of AI logistics.

Key Takeaways

- A unified AI dashboard brings together GPS, IoT, and telematics data to provide true end-to-end visibility of fleets and warehouse operations, leveraging EPD dashboards and Insights.

- Automated document generation and AI-powered regulatory lookup reduce manual effort and cut compliance errors.

- Predictive maintenance models analyze vibration and diagnostic data to forecast equipment failures and schedule repairs during idle periods.

- Integrated UWB sensors and computer-vision systems create a multi-layered safety net that detects personnel and machinery in blind spots.

- AI-driven staffing tools forecast demand, honor individual preferences, and generate balanced shift schedules that mitigate burnout.

- Intelligent route-planning algorithms optimize fuel usage, monitor real-time resource levels, and automatically plan refueling and parts-replacement tasks.

9 Wins Only AI In Logistics And Supply Chain Can Unlock

When AI algorithms join the warehouse crew, idle cranes, missing trucks, and guesswork forecasts vanish.

At JetRuby, our projects demonstrate how AI and supply chain technologies solve persistent challenges that drain time, money, and customer trust.

Here are just a few common issues companies face without AI in supply chain management:

- Dispatchers operate blindly during delays or route changes

- Fleet managers rely on manual calls to track vehicle location

- Empty runs go unnoticed until profit margins shrink

- Delivery estimates stay vague, leaving customers frustrated

- Drivers miss route changes or weather alerts in real time

AI tools eliminate these weak spots with fast data, predictive insights, and automated workflows.

How Does Artificial Intelligence Improve Supply Chain?

Leaders use AI for logistics to fix blind spots, reduce paperwork, and cut downtime. The following examples show how AI in the supply chain creates real value in critical operations.

Real-Time Visibility & Fleet Tracking

You send out dozens of trucks, containers, or vessels, but only hear updates after someone picks up the phone. Delays throw off the schedule. Empty runs drain margins. Without AI in logistics, dispatchers work blind during disruptions.

AI solution:

Our team built an AI-powered control tower for Anova Unify. It connects GPS, ELD, and IoT feeds into one dashboard. Dispatchers see a live map of fleets, facilities, and storage units across three countries.

Quick Tip: For an inside look at our methodologies, explore how we hire top engineers.

The platform supports over 90 filters and mobile tasking for crew members. It also predicts arrival times and flags route issues, even without a stable internet connection.

Result:

The system reduced empty runs and gave full visibility across operations. Teams respond faster, optimize capacity, and make better route decisions, all in real time.

Zero-Touch Paperwork

You spend hours filling CMRs and bills of lading, and errors in paperwork lead to fines. Staff devote long shifts to manual data entry, and typos trigger compliance issues.

AI solution:

JetRuby LLM smart AI assistant uses LLaMA 3 with retrieval-augmented generation (RAG). Crew members issue voice commands or text prompts to create acts, customs declarations, or find rules in PDFs or Word files. A secure vector store powers the model, so teams skip manual searches and get instant, accurate answers.

Result:

During our pilot, teams cut the time it took to find rules and forms by 90%. Now, they spend just 10% of the prior effort. Error rates among new hires fell by 70%, and annual operating costs dropped by $50,000 through lower labor hours and reduced compliance fees.

No More Costly Downtime

A single crane breakdown can stall port operations and drain budgets. Containers pile up, trucks idle, and the vessel racks thousands of dollars per hour in demurrage.

AI solution:

We place vibration sensors on each vehicle and crane. AI spots wear before failure and schedules repairs during layovers. Cameras and LiDAR steer lifts with one-centimeter accuracy and record each move. A safety engine maps motion paths and warns 10 seconds before a collision.

Pro Tip: Want to keep your best people? Check out our Top 13 Actionable Steps to Reduce Employee Turnover.

Result:

Service and repair costs fall, and fleets hit delivery windows without surprise breakdowns. Early alerts give yards fewer impacts and higher safety scores. These results prove that machine learning and supply chain work together to keep operations smooth.

Built-In Safety Shields

A forklift hides in a blind spot as workers move pallets nearby. Without warning, the driver turns and nearly hits a worker, causing a near-miss. Without a safety shield, this scenario repeats daily, increasing the risk of injury.

AI solution:

We combine Ultra-Wideband sensors and computer-vision cameras to create a 360° safety net around every vehicle. UWB tags track personnel and assets with 15 cm accuracy. The system alarms and stops equipment seconds before a collision.

These systems are as reliable in the field as a well-architected SaaS app in production. If you’ve read 9 Reasons Why Ruby on Rails Is Perfect for SaaS, you already know what that level of stability looks like.

Our CV module scans for hard hats and high-visibility vests. If it spots unprotected workers, it immediately locks down nearby vehicles. On top of that, a predictive-safety engine analyzes movement trajectories of people and machines.

Result:

Operations gain a multi-layered safety shield. Incidents in blind zones drop sharply. Equipment stays inactive only when truly necessary. And by logging every near-miss scenario, managers refine zone rules and drive continuous improvement in site safety.

Balanced Workloads, Happier Crews

Shifts burn out some teams while others sit idle because managers still build schedules by hand. Unbalanced rosters drive overtime up and increase employee turnover.

AI solution:

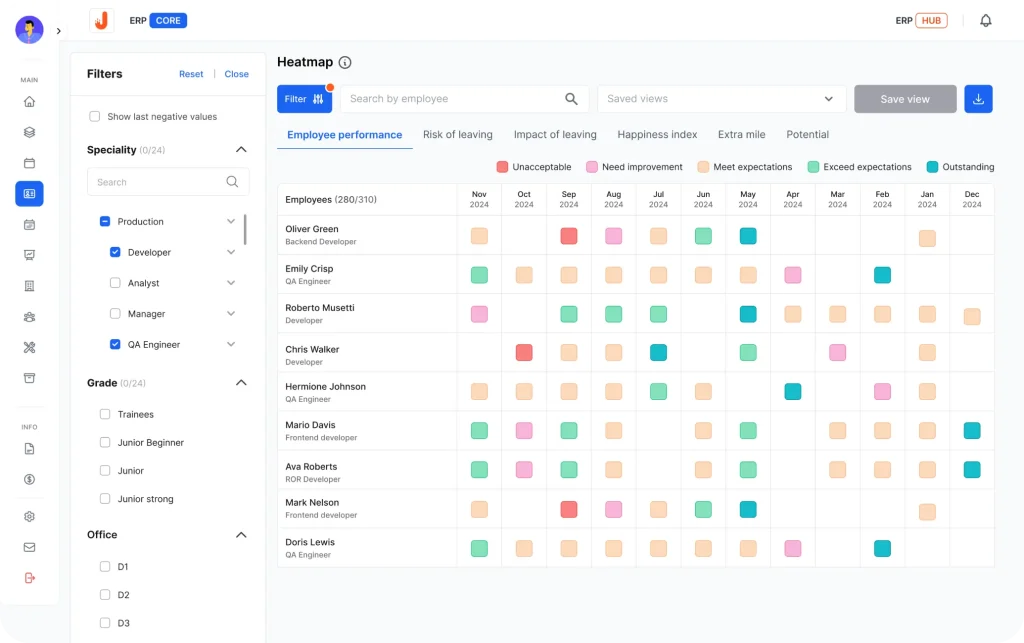

JetRuby’s workforce-planning system forecasts demand, gathers individual preferences, and generates optimal rosters. Its RMO module delivers heat maps of staff utilization, tracks vacations, sick leave, and training sessions, and adapts schedules automatically when variables change.

It’s built to scale, much like the platforms featured in 8 Best Ruby on Rails Hosting Providers, where performance and flexibility go hand in hand.

Result:

Optimized rosters cut turnover, thanks to more reasonable shift assignments and stronger engagement. Desertion drops when AI flags fatigue risks and proactively rebalances workloads. As a result, teams report a boost in satisfaction.

And because AI respects individual preferences rather than replacing roles, it actually elevates job satisfaction — explore why you shouldn’t fear of AI taking jobs in our dedicated post.

Fast Crew Reassignment

Unexpected leave or illness can stall a shipment for days when you scramble to find qualified replacements.

AI solution:

Our ERP recruitment module scans crew records for skills, certifications, and open slots. It returns a shortlist of ready drivers or seafarers in seconds. After you confirm a hire, the system reassigns tasks and alerts dispatchers, crew, and clients with one click.

Result:

Automated crew swaps cut average downtime, keeping schedules intact. Administrative overhead falls sharply as the platform handles credential checks and paperwork, freeing managers to focus on core operations.

Infinite IoT Scalability

Your pilot with 500 sensors worked smoothly, but adding the next thousand devices overloaded your servers.

AI solution:

We build a cloud-native LPWAN infrastructure — a clustered “umbrella” monitor scales to 100,000 devices per zone, handling both fixed sites and mobile container units. JetRuby integrates CI/CD pipelines for firmware and analytics, so each new device joins automatically without downtime.

Case in point:

A U.S. railroad company rolled out the system across four large stations and twenty key junctions. The carrier recorded a 15% revenue lift from stronger asset use and lower equipment loss.

Result:

Clients gain confidence to expand IoT coverage without server failures. Automated CI/CD ensures updates roll out smoothly as fleets grow, preserving performance and data integrity.

Predictive Fuel & Spares Planning

The fuel is burning out, crews hoard spare parts, and you only learn about shortages when it’s too late. Deliveries slip, penalties pile up, and clients question your reliability.

AI solution:

Our Python engine hosts 2 AI models, one projects fuel use, the other flags parts wear. When tanks run low or a part nears its limit, it routes trucks past the nearest fuel stop or parts depot. The dashboard shows live levels, sends alerts, and auto-creates refuel or parts tasks on the map.

Result:

A single consumption model lets teams react instantly in emergencies and avoids fuel spoilage and last-minute rush orders. Thanks to timely refills and on-time parts delivery, clients report a cut in fuel waste and a drop in spares logistics costs.

Quality Control at Machine Speed

Human inspectors often miss microfractures or surface defects, allowing damaged goods to reach customers and trigger costly returns.

AI solution:

We deploy a computer-vision system built on EfficientNetV3 for feature extraction and an R-CNN for precise region proposals and classification. High-resolution cameras scan each package on the conveyor belt in real time. This model lifts processing speed by 20-23%.

Result:

Implementations of this architecture deliver 20–23% faster defect-detection throughput compared to traditional machine-vision pipelines. Warehouse operations report an 18–25% drop in quality-related incidents, lowering rework and customer-return rates.

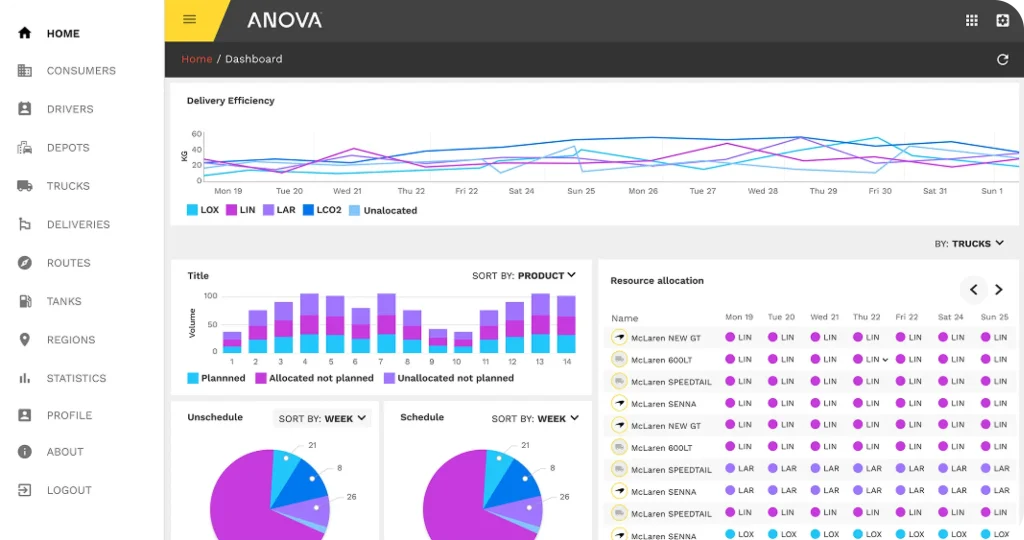

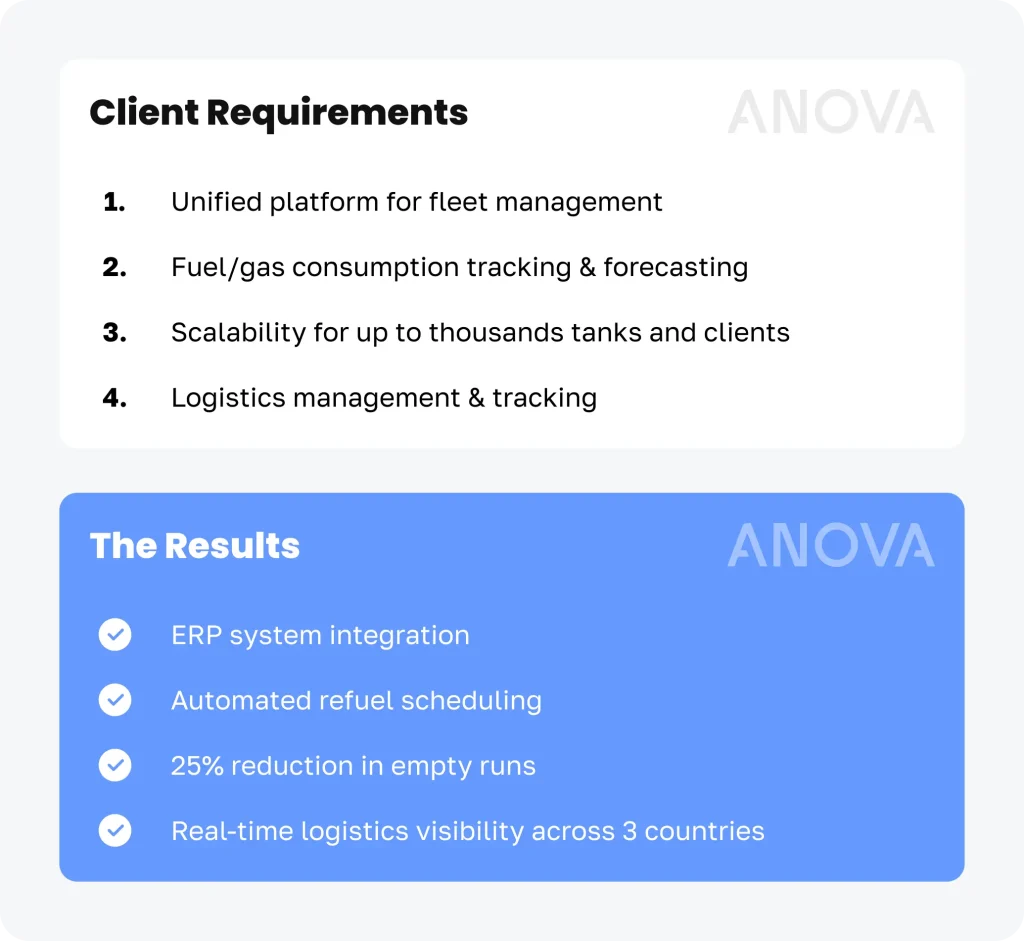

Anova Case Study: How AI Logistics Reduced Route Planning Time And Fuel Costs

The ANOVA platform oversees more than 600,000 assets for 1,500+ clients in about 70 countries and drives continuous growth across its unified toolset.

Pain Points Before AI In Supply Chain Management

ANOVA’s dispatchers spent up to six hours building daily routes for 20-30 trucks, while managers spent another five hours on phone calls to fix delays. Preparing a single delivery request could take three hours, leaving vehicles idle, incurring fines, and cutting revenue.

AI In SCM Solution: Our Approach

JetRuby assembled a cross-functional squad to deliver an automation platform that:

- Pulls live sensor data, predicts demand, and flags anomalies with AI supply-chain models

- Auto-generates optimal routes, waybills, and delivery requests

- Unifies vehicles, drivers, warehouses, and schedules on one dashboard

- Shows real-time status on interactive maps

- Enforces role-based access and enterprise-grade security

Benefits of AI in Logistics

The new system trims fuel loss through smarter routes, wipes out idle time and fines, and slashes manual planning and paperwork costs.

Managers now see every step of the fuel cycle, end-to-end, on a single screen, moving ANOVA to the next tier of operational efficiency. Read the complete ANOVA case study.

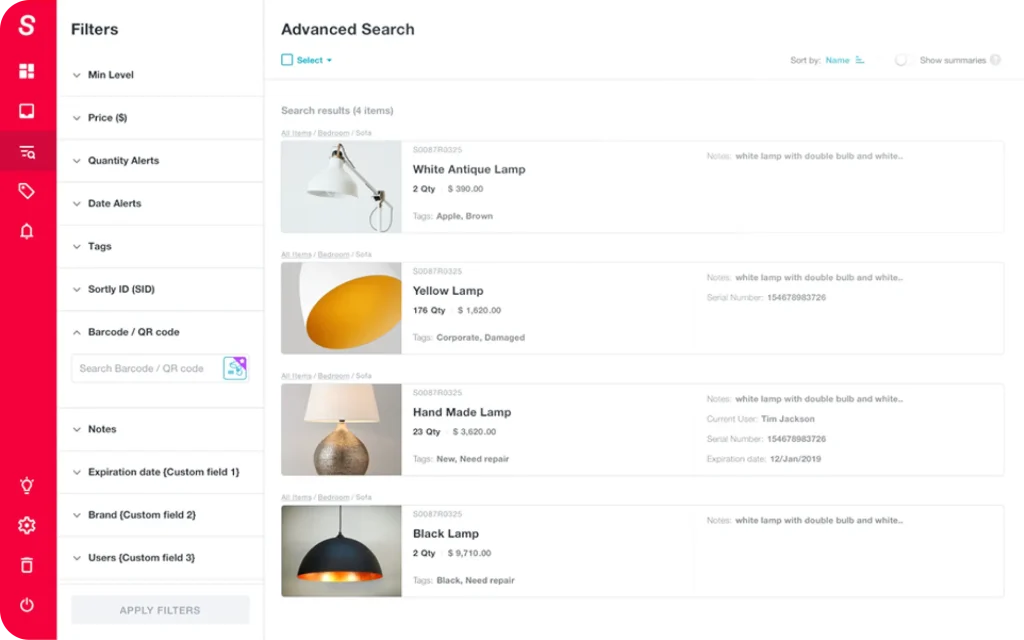

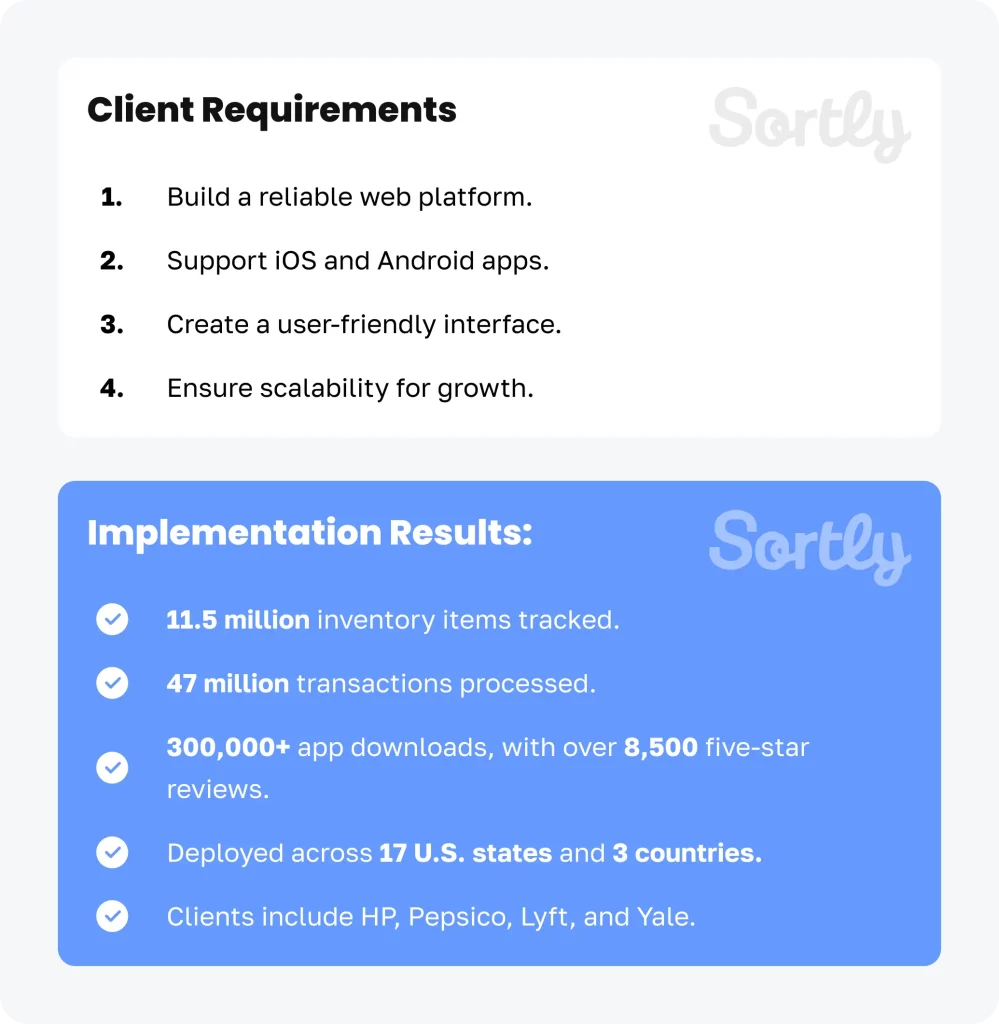

Sortly Case Study: AI In Supply Chain Management

Sortly is a top IOS inventory app. Its clear visual layout lets users easily track and sort items. They asked us to build a web platform that matches the mobile feel and supports bigger loads.

Hint: Like many mobile apps, Sortly thrives beyond App Store walls — see our List of 15 Alternative App Stores for 2025 to expand your distribution strategy.

Pain Before AI Supply Chain Management

Small crews juggled two separate apps yet still lacked end-to-end control. The older backend stalled when clients asked for payments, data import or export, dashboards, and ledger links. Rising user traffic pushed the system past its limit.

AI in SCM Solution: Our Approach

We’ve used Rails, Vue.js, QA, design, and product experts. We rebuilt data models, wrote over 1,000 tests, and kept work in brisk monthly sprints. The new web app shows a drag-and-drop view. Users scan barcodes, set custom fields, assign roles, and pull reports in seconds.

Benefits of AI Supply Chain Management: Real Results

Sortly’s key growth metrics following our engagement:

Inventory control moved from manual steps to a visual flow. Read the full Sortly case study.

AI in Logistics: JetRuby Delivers Proven Wins

Machine learning and AI in logistics unlock clear wins across every link in the supply chain:

- Real-time visibility across the fleet and warehouse

- Auto paperwork and instant route plans

- Predictive maintenance ends downtime

- Balanced workloads and safer yards

- Limitless IoT scale

- Lower fuel use and parts spent

- Vision systems find defects before shipment

Our case studies with ANOVA and Sortly prove these gains in action.

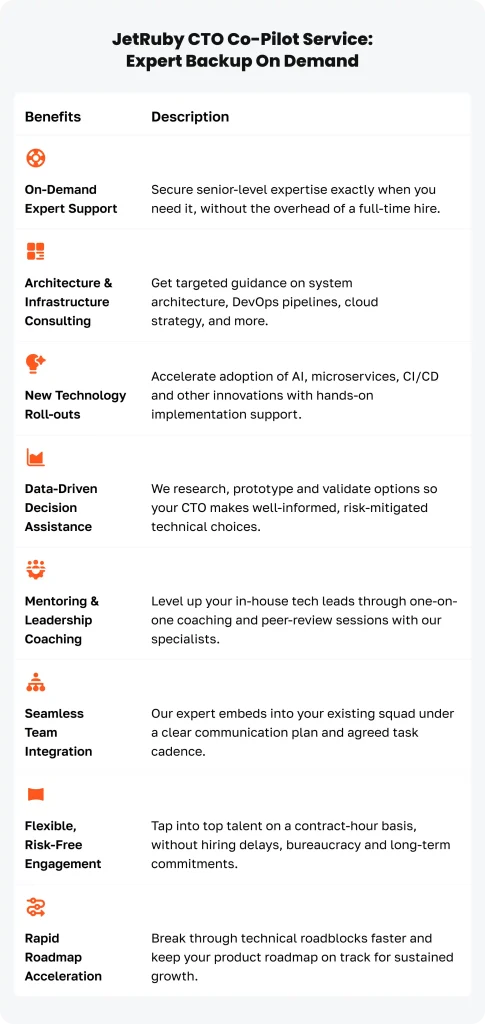

JetRuby CTO Co-Pilot Service: Expert Backup on Demand

Here’s how CTO Co-Pilot integrates with your team to deliver expert guidance exactly when you need it — fast, flexible, and without extra overhead. Review the key benefits below to see how you can close skill gaps and accelerate your technology roadmap.

CTO Co-Pilot steps in when the roadmap needs skills beyond the core stack. We assign a senior architect with deep cloud, AI, and DevOps insight to work directly with the in-house CTO. The expert fixes architecture gaps fast and shares proven patterns while the internal leader stays in charge.

Pro Tip: Hiring or leveling up leadership? Start with What Is a CTO? Unveiling the Truth About CTO Meaning in Business for a quick reality check.

The engagement starts with a brief audit that surfaces risks and quick wins. We outline scope, cost, and timeline, then code side by side with the team and guide each release until key metrics hold steady. When the system runs smoothly, the company moves forward on its own.

Ready to Transform Your Operations?

If you’re ready to move beyond pilots and embed artificial intelligence in supply chain management, use our Contact Us form to schedule a call, discuss your challenges, and map out a tailored development plan with JetRuby today.